Prepress is the term utilized in the publishing and printing sectors for the procedures and processes. The prepress procedure contains the fabrication of a printing plate, picture carrier prepared for mounting onto a printing press, in addition to the alteration of texts and images or the introduction of a high-quality printing document.

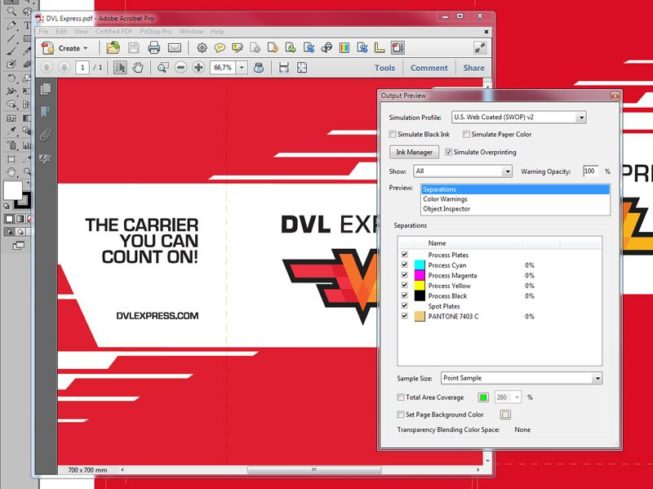

A lot of the prepress procedure is managed by experienced operators in commercial printing firms using proprietary software applications which are customized to their firms' particular requirements. They use software like Scribus, Adobe InDesign or QuarkXPress.

Without prepress, it is impossible to get the final product. It is the precondition for the transfer of ideas in the process of realization. If the prepress is done right, the product will meet customer expectations. Namely, in order to achieve the realization of the idea, it is necessary to know the types and kinds of printing, finishing process, types of paper, cardboard and other materials, which include printing process.

Although this phase is often neglected, it is important to point out that pre-press is crucial for the quality of the final product. An ignoring phase of pre-press, in order to reduce costs, usually results in having the opposite effect.